Replicator 2X Webcam Mount

The owner of the company I work for likes being able to show his business to his friends from out of town, so that and the need for some level of security means that there are cameras all over the building, including on the machines that have the more interesting jobs. When we got a 3D printer, we decided that there should be a web cam with a view of the build platform so that he could watch the printer work from afar, and so I started designing an adjustable platform for the (fairly old) camera that was given to me.

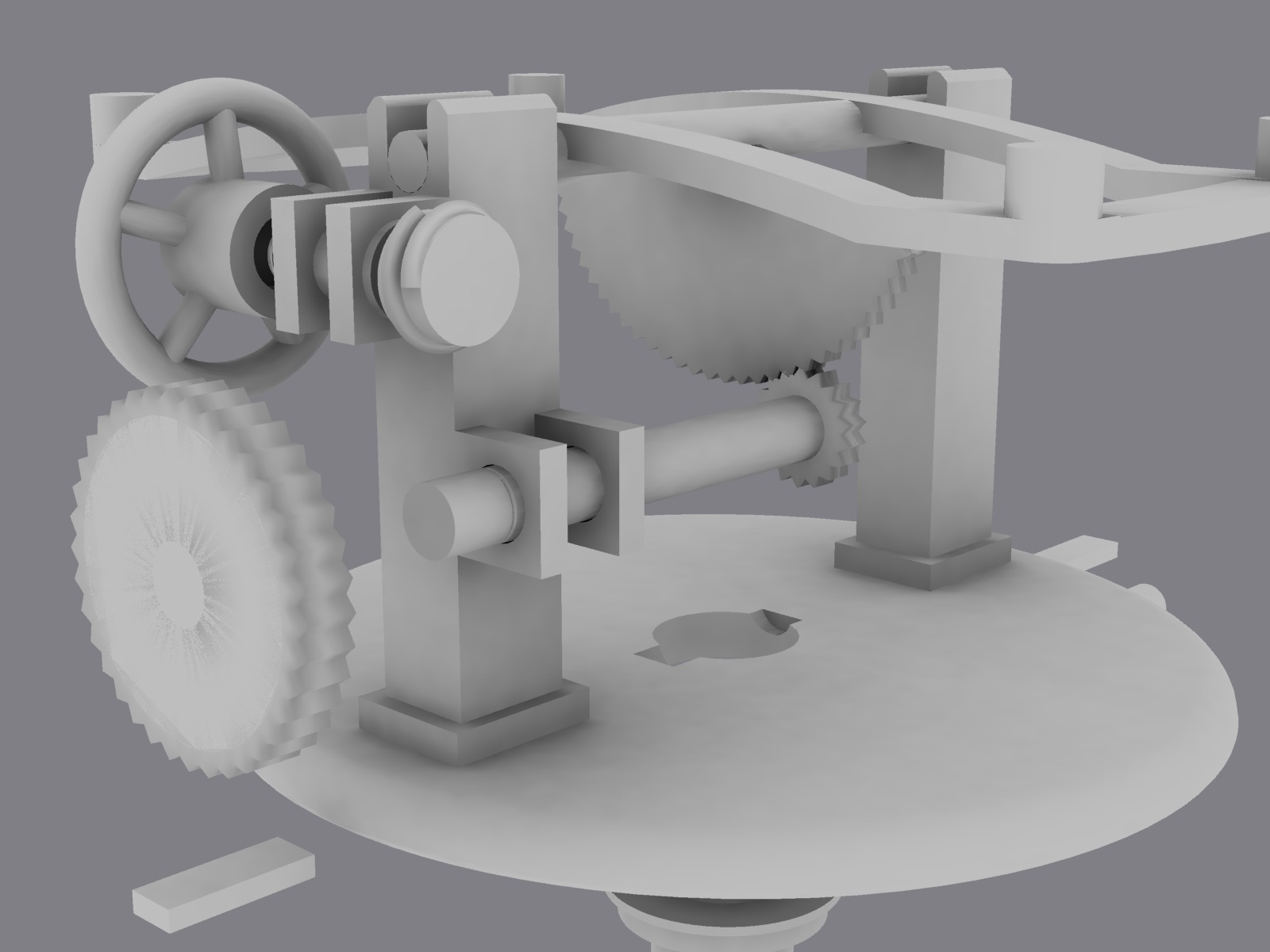

After making the dimensional cheat-sheet, I decided that the best way for the camera to attach to whatever platform I designed would be to utilize the recesses on the bottom of the camera where the screws that hold the device together are. After that, it was a pretty simple job to find the center of mass so I knew where to place the trunnions on the platform, and then I recruited a coworker to write a script that will generate a set of worm gears based on a few variables like center-to-center distance, outer diameter of the screw and the gear, and the inner diameter constraints of each part. The script then outputs an OBJ file which I could import as a mesh into Rhino 3D and position as necessary. The meshes have to overlap the NURBS objects in my model in order to print correctly, hence the need for inner diameter constraints. I went with worm gears because the screw is able to easily turn the gear, but the gear is unable to move the screw, so it’s not possible for the weight of the camera to move the platform out of position.

[RFG_gallery id=’2′]